The production process consists of three steps:

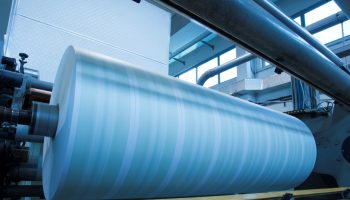

The Cast film process involves the extrusion of premium polymers melted through a flat die to form a thin multi-layer film. This film is laid down onto the surface of a water-cooled chill roll. The film quenches immediately and keeps its softness before winding. In the case of breathable film a machine direction stretching unit provides the required film breathability.

Films are extruded through a circular die and immediately inflated by air to obtain the best balance between MD and CD mechanical properties. In the case of breathable film a machine direction stretching unit provides the required film breathability.

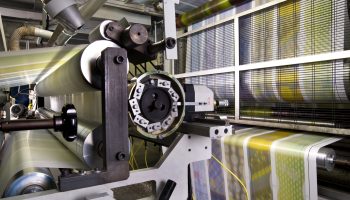

Hot melt adhesive lamination provides the flexibility to combine specific nonwovens typology to our film. It is possible to easily alter films or nonwovens to manufacture tailor made laminates according to Customers requests. Our lamination equipment grants the required bonding between the two layers, at the same time preserving the original softness of the non-woven fibers.